ALD Recipe

Updated on 9/26/2014

Contents

1 Basic concept of ALD

2 Process Sequence Table

3 Configuration of precursors

4 Recipes

4.1 Al2O3 deposition

4.1.1 Al2O3 grown with Trimethylaluminum (TMA) and H2O

4.1.2 Al2O3 grown with Trimethylaluminum (TMA) and O3

4.2 SiO2 deposition

4.2.1 SiO2 grown with 3-aminopropyltriethoxysilane (APTES), O3 and H2O

4.2.2 SiO2 growth with Tris(dimethylamino)silane (TDMASi or TDMAS) and O3

4.2.2.1 Old Recipe

4.2.2.2 New Recipe (9/8/2014)

4.3 TiO2 deposition

4.3.1 TiO2 grown with Tetrakis(dimethylamido)titanium (TDMAT) and H2O

4.3.2 TiO2 grown with Titanium isopropoxide (Ti(O-i-Pr)4) and H2O

4.4 HfO2 deposition

4.4.1 HfO2 grown with Tetrakis(dimethylamino)hafnium (HFDMA) and H2O

6 Advanced Page

7 Note

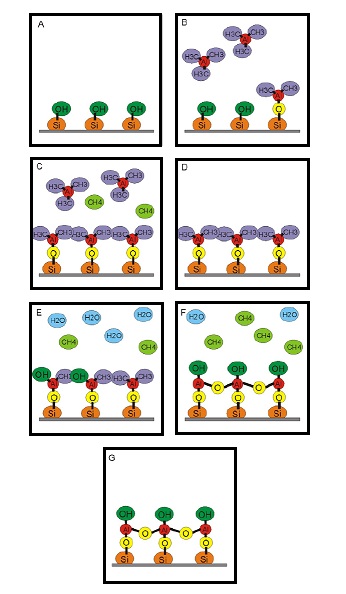

1. Basic concept of ALD

Atomic Layer Deposition (ALD) is a technique that allows growth of thin films, atomic layer by layer, using the reaction between precursor and hydroxylated surface. For example, Al2O3 layer is grown from water and trimethylaluminum (TMA), as shown below.

- Put in a sample which is hydroxylated from exposure to air, oxygen or ozone (figure A).

- Pulse the TMA precursor; TMA will react with the OH groups on the surface. TMA does not react with itself and the monolayer formed passivates the surface (figures B and C).

- Remove unreacted TMA molecules by evacuation and/or purging with nitrogen (figure D).

- Pulse water (H2O) into the reactor. This will remove the CH3 groups, create Al-O-Al bridges, and passivate surface with Al-OH. CH4 (methane) is formed as a gaseous byproduct (figures E and F).

- Remove unreacted H2O and CH4 molecules by evacuation and/or purging with nitrogen (figure G).

See the following review article: Overview_of_ALD

2. Process Sequence Table

- This table allows programming, loading and saving of the sequence of a process (recipe).

- Editing of the table is accomplished by selecting commands in a context menu (right-click menu) and typing in numerical values. After right click, the row that the mouse cursor is pointing to becomes selected and is highlighted with a blue frame.

- Each command line in the table consists of an automatically assigned line number, an instruction, and two numerical parameters: “#” and “value”.

2.1 Clicking on the following menu items

- Loading/Saving a recipe: a load/save file dialog shows up, allowing access to recipe files saved in computer data storage.

- Insert Row Before: adds a new row before the selected row.

- Delete Row: deletes the selected row.

- Empty Table: erases all in the table.

2.2 Adding/Changing an instruction (command)

- pulse (#, value): opens the “#”-th ALD valve for “value” seconds and then closes the valve, which completes a precursor pulsing. The valid value of “#” is 0,1,2,3,4, and 5, corresponding to the 2-pin socket that the ALD valve is connected to on the electronic box. The range of “value” is 0.010 to 10.

- wait (, value): lets the program to wait “value” seconds before executing the next command. This command is usually used right after a “pulse” command for purging the pulsed precursor. “value” can be any non-negative number.

- goto (#, value): jump to line number “#” for “value” times. “#” must be a non-negative integer and no greater than the largest line number in the recipe. “value” must be a positive integer.

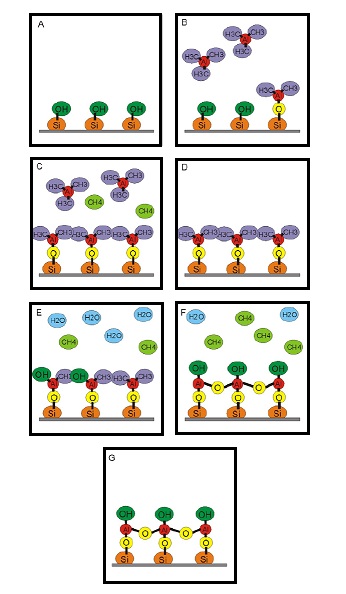

- Line 0 to 4 corresponds to the growth of 800 cycles of the first material using precursors 0 and 1.

- Line 5 to 9 corresponds to the growth of 700 cycles of the second material using precursors 0 and 4.

- Line numbers of both goto instruction and the line that goto jumps to are colored to help identify the range of a goto loop.

- It is advised to double-check all the parameters in a process sequence before starting a run.

- heater (#, value): sets number of heater (6-17) and temperature.

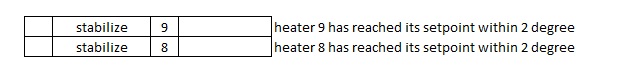

- stabilize (#): waits until heater # has reached its setpoint within 2 degree.

- flow (, value): sets the flow rate to “value”, which can be any non negative number. However, the actual flow rate is limited by the specifications of the mass flow controller in use.

- stopvalve (, value): closes (value=0) or opens (value=1) the stop valve for pumping/venting the chamber.

- line ac out (#, value): turns the #-th 120V output on (value=1) or off (value=0).

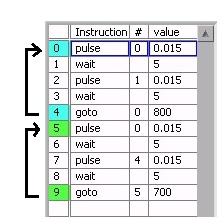

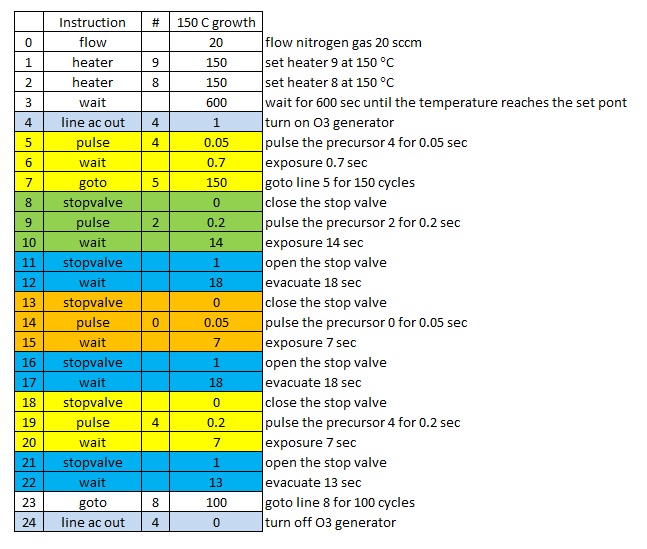

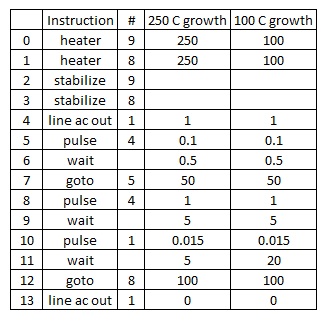

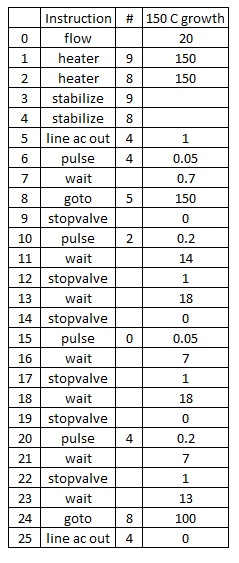

2.3 Example of recipe

The following Process Sequence Table shows an example of recipe:

Detail:

- Line 0: sets flow of nitrogen gas at 20 sccm.

- Lines 1-2: sets heaters 8 and 9 at 150 ºC.

- Line 3: waits for 600 sec until the temperature of the reactor reaches the set point. This line could be replaced by the following 2 lines.

- Line 4: turns on ac line 4 for ozone generator.

- Line 5: opens the valve 4 for 0.05 sec.

- Line 6: exposes the vapor of the precursor 4 onto the substrate for 0.7 sec.

- Line 7: goes to line 5 for 150 cycle loop between 5 and 7.

- Line 8: closes the stop valve to the vacuum pump.

- Line 9: opens the valve 2 for 0.2 sec to set up the vapor pressure of the precursor 2.

- Line 10: exposes the vapor of the precursor 2 onto the substrate for 14 sec.

- Line 11: opens the stop valve to the vacuum pump.

- Line 12: evacuates the reactor for 18 sec.

- Lines 13-15: See lines 8-10.

- Lines 16-17: See lines 11-12.

- Lines 18-20: See lines 8-10.

- Lines 21-22: See lines 11-12.

- Line 23: goes to line 8 for 100 cycle loop between 8 and 23.

- Line 24: turns off ac line 4 for ozone generator.

- Note:

- The stop valve is closed for isolation of the reactor to control the vapor pressure of the precursor exposed onto the substrate when the precursor is introduced into the reactor.

- The pulse time should be adjusted to control the vapor pressure of the precursor.

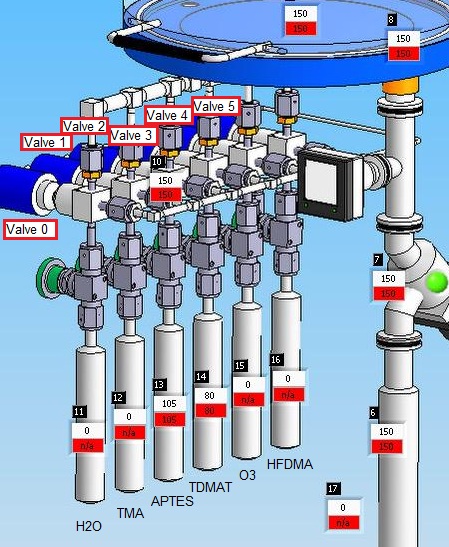

3. Configuration of precursors

Heater 11: Valve 0, H2O, No heater

Heater 12: Valve 1, Trimethylaluminum (TMA) for Al2O3 deposition, No heater

Heater 13: Valve 2, 3-aminopropyltriethoxysilane (APTES) for SiO2 deposition, 105 °C

Heater 14: Valve 3, Tetrakis(dimethylamido)titanium (TDMAT) for TiO2 deposition, 75 °C

Heater 15: Valve 4, Ozone, No heater

Heater 16: Valve 5, Tetrakis(dimethylamino)hafnium (HFDMA), 75 °C

4. Recipes

- Note:

- The Savannah film recipes provided by Cambridge Nano Tech are posted.

- Optimization of precursor dose and exposure is still required.

4.1 Al2O3 deposition

4.1.1 Al2O3 grown with Trimethylaluminum (TMA) and H2O

- Note: This precursor is installed in Nanofab.

Growth rates: 0.91 Å/cycle@150°C, 1.0 Å/cycle@200°C, 0.94 Å/cycle@250°C, 1.0 Å/cycle@300°C

Recipe:

Precursors: Al(CH3)3 Trimethylaluminum (TMA), H2O

300°C growth:

- 9=300°C, 8=270°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015s

- wait 3s

- pulse TMA (Valve 1), 0.015s

- wait 3s

250°C growth:

- 9=8=250°C, 6=7=10=150°C,flow=20sccm

- pulse H2O (Valve 0), 0.015s

- wait 5s

- pulse TMA (Valve 1), 0.015s

- wait 5s

200 °C growth

- 8=9=200 °C, 6=7=10=150 °C, flow=20sccm

- pulse H2O (Valve 0), 0.015s

- wait 8s

- pulse TMA (Valve 1), 0.015s

- wait 8s

150°C growth

- 8=9=150°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015s

- wait 20s

- pulse TMA (Valve 1), 0.015s

- wait 20s

80°C growth

- 8=9=80°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015s

- wait 30s

- pulse TMA (Valve 1), 0.015s

- wait 30s

- Line 8 indicates 100 cycles.

4.1.2 Al2O3 grown with Trimethylaluminum (TMA) and O3

Growth rates: 0.6 Å/cycle@100°C, 0.9 Å/cycle@250°C

Recipe:

precursors: TMA, O3

250°C growth:

- 8=250°C, 9=250°C, 6=7=10=150°C, flow=20sccm

- pulse O3 (Valve 4), 1s

- wait 5s

- pulse TMA (Valve 1), 0.015s

- wait 5s

100°C growth:

- 8=9=100°C,6=7=10=150°C,flow=20sccm

- pulse O3 (Valve 4), 1s

- wait 5s

- pulse TMA (Valve 1), 0.015s

- wait 20s

- Line 12 indicates 100 cycles.

4.2 SiO2 deposition

4.2.1 SiO2 grown with 3-aminopropyltriethoxysilane (APTES), O3 and H2O

- Note: This precursor is installed in Nanofab.

Growth rates: 0.72 Å/cycle@150°C

Recipe:

Precursors: H2N(CH2)3Si(OC2H5)3 3-aminopropyltriethoxysilane (APTES) heated to 105°C

CAS Registry Number#: 919-30-2

water (unheated)

ozone (unheated)

- Recipe modified from: Bachmann J. et al. Angewandte Chemie International Edition, 2008, 47, 6177.

- Note: Optimization of precursor dose and exposure still required*

150°C growth:

- 8=9=150°C, 6=7=10=150°C, flow=20sccm

- Ozone installed onto port 4

- Line 4 – turns on O3 generator

- Lines 5-7 – purge and prime O3 line

- Pulse ozone (valve 4) for 0.2 sec, expo 7 sec, purge 13 sec

- Line 24 – turn off O3 generator

- H2O Installed onto port 0

- Pulse water 0.05 sec, expo 7, purge 18 sec

- 3-aminopropyltriethoxysilane installed onto port 2, heated to 105°C

- Pulse H2N(CH2)3Si(OC2H5)3 (Valve 2) , 0.2 sec, expo 14 sec, purge 18 sec

- Line 23 indicates 100 cycles.

4.2.2 SiO2 growth with Tris(dimethylamino)silane (TDMASi or TDMAS) and O3

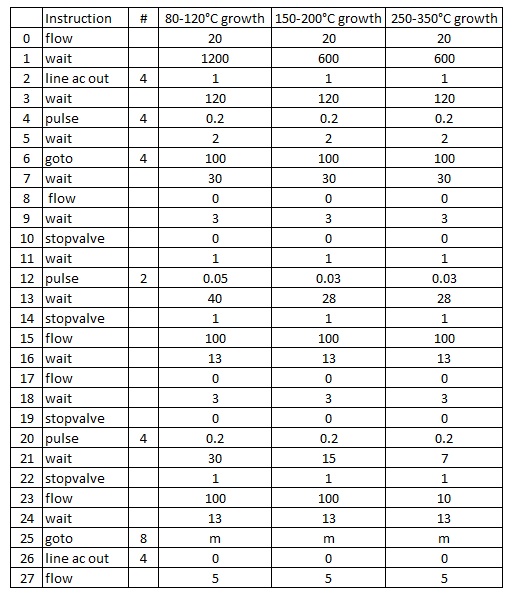

Old Recipe

Precursors: [(CH3)2N]3SiH, Tris(dimethylamino)silane (TDMASi)

CAS#: 15112-89-7

Ozone, O3 (Unheated)

Tris(dimethylamino)silane installed onto port 2, unheated

Ozone installed onto port 4

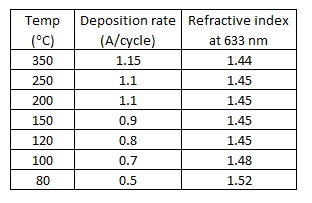

80-120°C growth:

- 8=9=80-100°C, 6=7=10=150°C.

- 80°C growth rate ~ 0.5 Å/cycle, refractive index (633nm) ~1.52

- 100°C growth rate ~ 0.7 Å/cycle, refractive index (633nm) ~1.48

- 120°C growth rate ~ 0.8 Å/cycle, refractive index (633nm) ~1.45

- Line 2: turn on O3 generator

- Lines 3-5: purge and prime O3 line

- Lines 7-15 : pulse TDMASi (Valve 2) , 0.05 sec, expo 40 sec, purge 13 sec

- Lines 16-23: pulse ozone 0.2 sec, expo 30 sec, purge 13 sec

- Line 25: m number of cycles

- Line 26: turn off O3 generator

150-200°C growth:

- 8=9=150-200°C, 6=7=10=150°C

- 150°C growth rate ~ 0.9 Å/cycle, refractive index (633nm) ~1.45

- 200°C growth rate ~ 1.1 Å/cycle, refractive index (633nm) ~1.45

- Lines 7-15 : pulse TDMASi (Valve 2) , 0.03 sec, expo 28 sec, purge 13 sec

- Lines 16-23: pulse ozone 0.2 sec, expo 15 sec, purge 13 sec

250°C growth:

- 8=9=250°C, 6=7=10=150°C

- 250°C growth rate ~ 1.1 Å/cycle, refractive index (633nm) ~1.45

- Lines 7-15 : pulse TDMASi (Valve 2) , 0.03 sec, expo 28 sec, purge 13 sec

- Lines 16-23: pulse ozone 0.2 sec, expo 7 sec, purge 13 sec

300~350°C growth:

- 8=280°C, 9=300-350°C, 6=7=10=150°C

- 350°C growth rate ~ 1.15 Å/cycle, refractive index (633nm) ~1.44

- Lines 7-15 : pulse TDMASi (Valve 2) , 0.03 sec, expo 28 sec, purge 10 sec

- Lines 16-23: pulse ozone 0.2 sec, expo 7 sec, purge 10 sec

- Line 25 indicates "m" cycles.

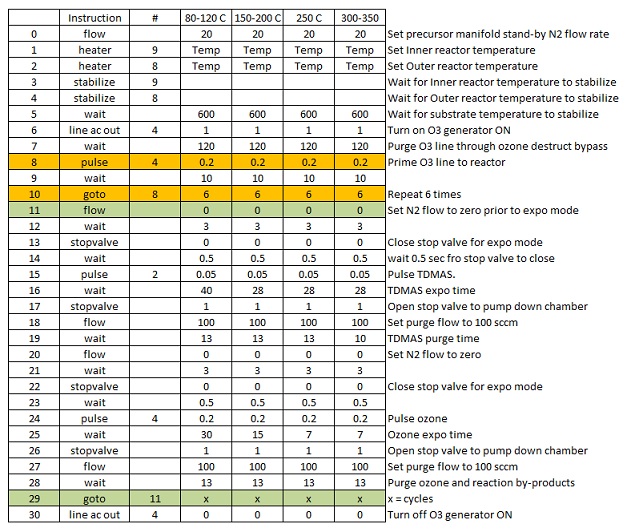

New Recipe (9/8/2014)

Reference: SiO2_from_TDMAS_and_ozone_ALD2011

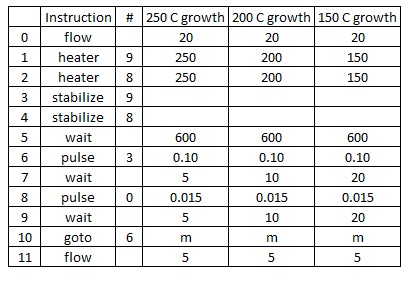

4.3 TiO2 deposition

4.3.1 TiO2 grown with Tetrakis(dimethylamido)titanium (TDMAT) and H2O

- Note: This precursor is installed in Nanofab.

CAS#: 3275-24-9

Recipe:

Precursors: Ti(NMe2)4 Tetrakis(dimethylamido)titanium (TDMAT) heated to 75°C and H2O (unheated)

250°C growth:

- 8=9=250°C, 6=7=10=150°C, flow=20sccm

- pulse TDMAT (Valve 3) , 0.1 pulse

- wait 5s

- pulse H2O (Valve 0) , 0.015sec pulse

- wait 5s

- Growth per cycle: ~0.39Å/cycle

- Refractive Index: between 2.1-2.5 depending on film thickness

200°C growth:

- 8=9=200°C, 6=7=10=150°C, flow=20sccm

- pulse TDMAT (Valve 3) , 0.1 pulse

- wait 10s

- pulse H2O (Valve 0) , 0.015sec pulse

- wait 10s

- Growth per cycle: ~0.40Å/cycle

- Refractive Index: between 2.2-2.5 depending on film thickness

150°C growth:

- 8=9=150°C, 6=7=10=150°C, flow=20sccm

- pulse TDMAT (Valve 3) , 0.1 pulse

- wait 20s

- pulse H2O (Valve 0) , 0.015sec pulse

- wait 20s

- Growth per cycle: ~0.40Å/cycle

- Refractive Index: between 2.2-2.5 depending on film thickness

- Line 10 indicates "m" cycles.

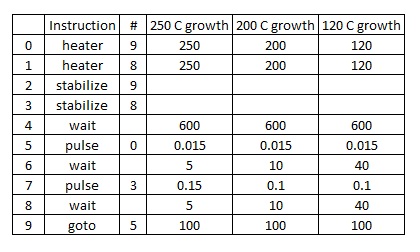

4.3.2 TiO2 grown with Titanium isopropoxide (Ti(O-i-Pr)4) and H2O

Growth rates: 0.123 Å/cycle@120°C, 0.36 Å/cycle@200°C, 0.35 Å/cycle@250°C

Recipe:

Precursors: Ti{OCH(CH3)2}4 Titanium isopropoxide heated to 80°C and H2O (unheated)

250°C growth:

- 8=9=250°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015sec

- wait 5s

- pulse Ti{OCH(CH3)2}4 (Valve 3) , 0.15 sec

- wait 5s

200°C growth:

- 8=9=200°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015sec

- wait 10s

- pulse Ti{OCH(CH3)2}4 (Valve 3) , 0.10 sec

- wait 10s

120°C growth:

- 8=9=120°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015sec

- wait 40s

- pulse Ti{OCH(CH3)2}4 (Valve 3) , 0.10 sec

- wait 40s

- Line 9 indicates 100 cycles.

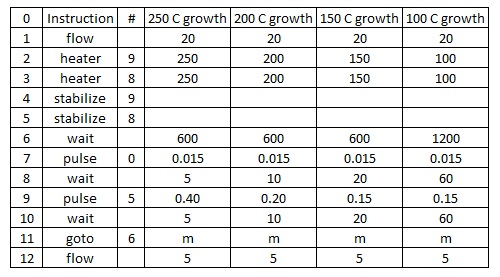

4.4 HfO2 deposition

4.4.1 HfO2 grown with Tetrakis(dimethylamino)hafnium (HFDMA) and H2O

- Note: This precursor is installed in Nanofab.

Precursors: Hf[N(CH3)2]4, Tetrakis(dimethylamino)hafnium (HFDMA, Hf(NMe2)4) heated to 75°C and H2O (unheated)

250°C growth:

- 8=9=250°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015sec

- wait 5 s

- pulse Hf(NMe2)4 (Valve 5) , 0.40 sec

- wait 5 s

- Growth rate per cycle: 0.98Å /cycle on silicon

200°C growth:

- 8=9=200°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015sec

- wait 10 s

- pulse Hf(NMe2)4 (Valve 5) , 0.20 sec

- wait 10 s

- Growth rate per cycle: 1.01Å /cycle on silicon

- Refractive Index: 2.092 @ 632nm (1000 Å Film)

150°C growth:

- 8=9=150°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015sec

- wait 20 s

- pulse Hf(NMe2)4 (Valve 5) , 0.15 sec

- wait 20 s

- Growth rate per cycle: 1.04Å /cycle on silicon

100°C growth:

- 8=9=100°C, 6=7=10=150°C, flow=20sccm

- pulse H2O (Valve 0), 0.015sec

- wait 60s

- pulse Hf(NMe2)4 (Valve 5) , 0.15 sec

- wait 60s

- Growth rate per cycle: 1.12Å /cycle on silicon

- Line 11 indicates "m" cycles.

6. Note

- Valve number in the above recipes might be changed. Make sure of the valve number of the precursor gas before use.

- Ozone dose (pulse time) and O2 flow rate etc. are strongly dependent on the actual setup of your ozone generator. Refer to your ozone generator instructions for recommended settings, and make adjustments if necessary. Limit peak pressure to below 600 Torr during the ozone exposure step to prevent from over pressure or venting to atmosphere.

- When an ozone process is aborted or interrupted after the ozone generator is turned on but before the “line ac out 1 0“ command is executed, the ozone generator will be left on indefinitely until turned off manually. If it will not be used soon, run the short recipe below to turn the ozone generator off: line ac out 1 0

- N2 flow is turned off during expo steps to allow precursors to have the same exposure over the entire reactor, especially for TDMASi because of its low reactivity.

- This recipe works for flat surfaces. For deep vias and trenches, it may not provide adequate precursor dose deep within the pores - increasing exposure time or precursor dose accordingly.