Helium from Natural Gas

(recommended by William B. Retallick, Consultant)

Over 99% of helium manufactured is as a coproduct of natural gas processing. In addition to recovering helium, nitrogen is removed so that the gas can be sent to market through a pipeline. In these plants, compressors are driven by gas turbines that are fueled with a mixture of methane and nitrogen. This reduces the separation work necessary.

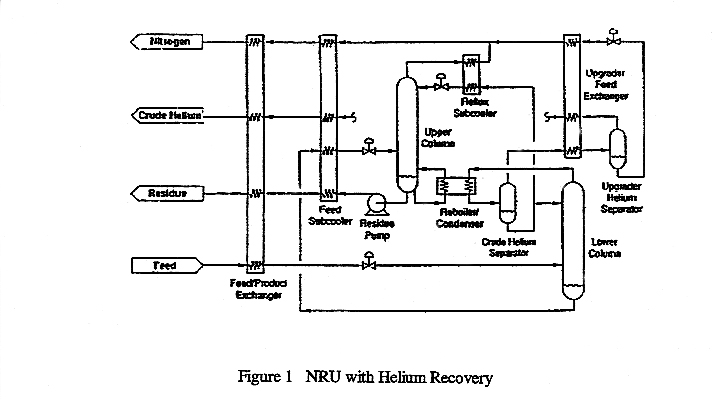

The flow diagram in Figure 1 is from Union Carbide (1) and is called the double-column cycle. In this project, you will find the pressures in the two columns that minimize the power input to the plant. Furthermore, you should consider whether it is more efficient to pass the feed through a turbo-expander rather than a Joule-Thompson valve. The turbine fuel contains at least 45% CH4, with the balance N2, and is delivered to the turbines at 10-15 atm. You should decide which column it comes from.

In a previous design report, Cryogenic Nitrogen Separation (1998), it was shown that a process that removes nitrogen only is uneconomical when the feed cost ($/MMBtu) exceeds about 10% of the value of the sales gas. If the present plant is to be economical, it must result from the sales of the recovered helium ($/MCF).

The design basis is:

50 Million SCFPD at 800 psig

Gas Composition (mol%)